Navigate to:

The Rotterdam refinery is one of the most energy efficient of its kind in Europe. Since being put into operation in 1960, the plant has undergone several renovations. The sizeable capital investments through the years have made the refinery ultra-efficient.

The refinery processes different grades of crude oil varying from light low-sulphur to heavy high-sulphur oil. The crude oil is supplied by ship and stored at the tank farms on the Maasvlakte and in Europoort. It is transported from the tank farms to the refinery via pipelines where it is processed into a range of products, such as LPG, kerosene and diesel. Thanks to the Flexicoker unit, the refinery has not produced any heavy fuel oil since the 1980s.

Hydrocracker expansion

The most recent update was the expansion of the hydrocracker, an investment of over a billion dollars. The new, advanced hydrocracker was commissioned in 2019. With this installation, the refinery now produces not only fuels and chemical feedstocks but also high-quality base oils (basestocks) for a new generation of lubricants.

Energy efficient

The refinery has its own cogeneration unit (Cogen), which utilizes low-calorie gas from the Flexicoker to produce electricity and steam. As a result, emissions of SOx and NOx, dust and aromatics are significantly lower than they are at other refineries. The Cogen provides most of the energy needs of the refinery complex. The new hydrocracker has increased the refinery's energy efficiency by five percent.

Greater efficiency through integration

The refinery is almost completely integrated with the neighbouring aromatics plant. The refinery supplies the basic raw materials to the aromatics plant, which, in turn, sends by-products back to the refinery for further processing. Since 2011, the refinery has also been integrated with Air Products' ultra-modern hydrogen plant, which is situated on the same site. The hydrogen plant uses residual gasses from the refinery to produce liquid hydrogen. On its turn, the Air Products plant delivers hydrogen and heat (steam) to the refinery. The hydrogen is used to desulphurize oil and to be able to produce cleaner fuels. The integration of different plants has helped optimize energy efficiency and reduced CO2 emissions.

Esso Nederland B.V.

Rotterdam Refinery

Botlekweg 121

3197 KA Rotterdam-Botlek

Havennummer 4060

The Netherlands

Tel.: +31 (10) - 493 5911

VAT number: NL.0010.27.311.B01

Company reg. no.: 27004771

Registered office: Rotterdam

Products:

- LPG

- naphtha

- kerosene

- diesel fuel

- sulfur

- petroleum cokes

- various raw materials for the chemicals industry

The Rotterdam Aromatics Plant is one of the largest aromatics production facilities in the world. The plant was built in 1963 next door to the refinery, from which it receives its basic raw materials. The plant is one of the few facilities in the world that can produce the entire range of aromatic hydrocarbons.

It produces pure aromatics, such as benzene, orthoxylene, paraxylene and cyclohexane. The aromatics made at the plant find their way into countless products we use every day, for example, packaging and insulation material - such as PET bottles and polystyrene foam - plastic used in electric (kitchen) appliances, car parts and sports shoes, and synthetic fibers and resins.

Capacity expansion

The paraxylene production capacity has expanded ten-fold over the years. The most recent expansion in 2009 - involving an investment of tens of millions of euros - increased the production capacity for paraxylene and benzene by 20 per cent and made the aromatics plant one of the largest paraxylene producers in the world. The expansion also led to a decrease in energy consumption per tonne product by 15 percent.

Efficiency through integration

The aromatics plant is almost completely integrated with the neighbouring refinery, from which it receives its basic raw material. The by-products from the aromatic plant's production process are in turn sent back to the refinery for further processing. Besides the more flexible supply of raw materials, integrating the plant and the refinery has led to significant energy savings and cost reductions.

ExxonMobil Chemical Holland B.V.

Rotterdam Aromatics Plant

Botlekweg 121

3197 KA Rotterdam-Botlek

Havennummer 4060

The Netherlands

Tel.: + 31 (0)10 - 493 59 11

VAT number: NL.0048.23.187.B01

Company reg. no.: 24231768

Registered office: Rotterdam

Products:

- Aromatics:

- benzene,

- paraxylene,

- orthoxylene

- Cyclohexane

Officially called the Rotterdam Plasticizers & Intermediates Plant, the Rotterdam Oxo-alcohols Plant actually comprises three production facilities: the Rotterdam Oxo-Alcohol Plant in Europoort, the Phthalic Anhydride Plant and the Rotterdam Plasticizer Plant, which are both located in Rotterdam Botlek. It is the largest producer of plasticizers in Europe.

The three facilities of the Rotterdam Plasticizers & Intermediates Plant are closely integrated together and with the refinery. The fact that they are so far apart is the result of the various takeovers and acquisitions that have taken place in ExxonMobil's history. In terms of production, the facilities form a logical whole: oxo-alcohols and phthalic anhydride are both raw materials for plasticizers.

Plasticizers make 'hard' plastic soft and pliable. They are used to make products such as cables, textiles, wallpapering, carpeting, furniture and footwear flexible.

Efficient transport

The raw materials for oxo-alcohols are supplied by ship. Thanks to investments made in 2016 in, for example, better loading facilities, the raw materials can be supplied by larger ships and the number of sea transport operations has been halved. This has contributed to improving the plant's efficiency and environmental performance.

ExxonMobil Chemical Holland B.V.

Rotterdam Plasticizers & Intermediates Plant

Rotterdam Oxo-Alcohol Plant

Merwedeweg 21, havennummer 5625

3198 LH Europoort

Rotterdam

The Netherlands

Tel: +31 (0)10 493 3600

VAT number: NL.0048.23.187.B01

Company reg. no.: 24231768

Registered office: Rotterdam

ExxonMobil Chemical Holland B.V.

Rotterdam Plasticizers Plant

Phtalic Anhydride Plant

Welplaatweg 2

3197 KS Botlek, Rotterdam

Havennummer 4101

The Netherlands

Tel.: +31 (0)10 493 4579

VAT number: NL.0048.23.187.B01

Company reg. no.: 24231768

Registered office: Rotterdam

Products:

- Exocal alcohols

- Jayflex plasticizers

The Pernis Lubricant Plant – or Lube Oil Blending Plant – produces various types of engine oil for trucks and lubricants for industrial applications.

The plant mixes base oils and special additives to make hundreds of lubricants for widely ranging purposes. Each lubricant has its own specifications and preparation method. The products vary from high-viscosity engine oil to ultra-fine lubricants for wind turbines. All the products are subjected to extensive quality assurance testing in the plant's laboratory. The Pernis Lube Oil Blending Plant only makes mineral-oil products; the synthetic lubricants for customers in the Benelux are imported from ExxonMobil plants in France and Finland.

The lubricants are transported via pipelines to inland waterway barges or tanker trucks, or they are stored in the warehouse in barrels and cans before they are collected.

ExxonMobil Lube Oil Blending Plant

Butaanweg 161

3196 KC Pernis

Havennummer 3018

Postbus 160

3190 AD Hoogvliet

The Netherlands

Tel.: +31 (0)10 - 496 1000

VAT number: NL.0010.27.311.B01

Company reg. no.: 27004771

Registered office:Rotterdam

Products:

Various lubricants for:

- general industry, for example, Mobilgears, Spartan's, Teresstic, Nuto, DTE 20, Vacuoline, Mobil SHC, Mobilgrease;

- truck engines, for example, Mobil 1, Esso Ultra, Delvac;

- shipping, for example, Mobilgard.

Explore more

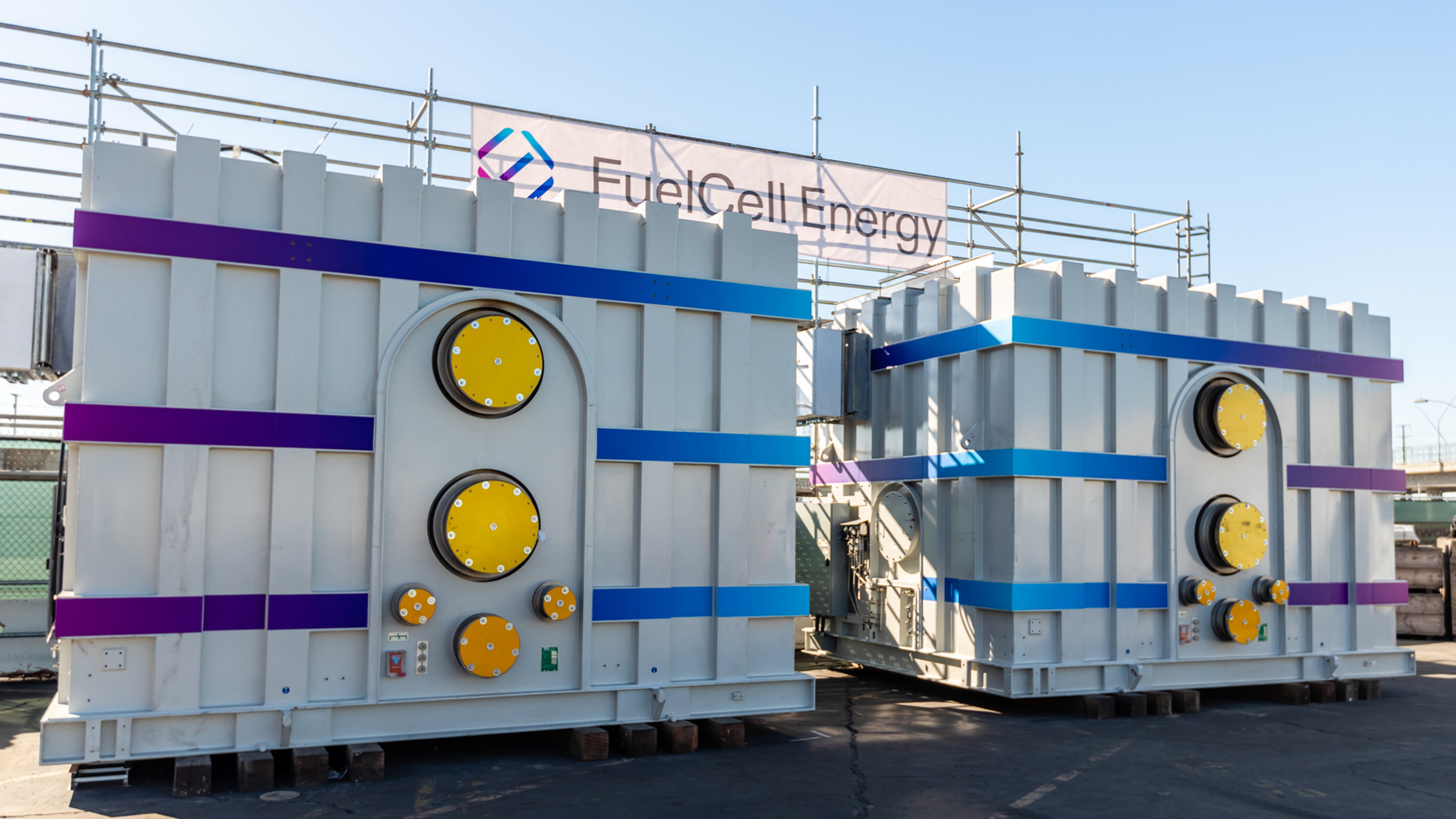

ExxonMobil to build CCS pilot plant with FuelCell Energy using carbonate fuel cell technology

2 min read

•

Neptune Energy, ExxonMobil, Rosewood and EBN to cooperate on L10 carbon capture and storage

2 min read

•

Local career initiatives

5 min read

STEM initiatives

4 min read

Max Verstappen surprises ExxonMobil employees in Rotterdam

2 min read

Meet our people

8 min read