4 min read

•Powering plastics recycling in Southeast Asia

4 min read

•ExxonMobil is working to collaborate with governments, industry and technology providers throughout Southeast Asia to help assess the potential for large-scale advanced recycling facilities across the region, developing technology and supporting policies that help to accelerate plastic waste collection and recycling in order to support the creation of a circular economy for plastics.

“Plastics can help to raise living standards around the world, given their critical use in agriculture, food packaging, medical equipment and more,” said Wai-Kong Choy, ExxonMobil’s advanced recycling project manager for Asia Pacific.

“Leveraging the technologies and expertise of organizations across the value chain, we can help accelerate a circular economy for plastics in the Southeast Asia region, so that a broader scope of plastic waste can be turned into new products instead of ending up in the environment, incineration or landfill.”

What is Advanced Recycling?

Less than 10% of plastic waste is recycled globally, in part due to challenges with the collection and sorting of plastic waste, particularly items made from different types of plastics or products contaminated with food waste or sticky labels.

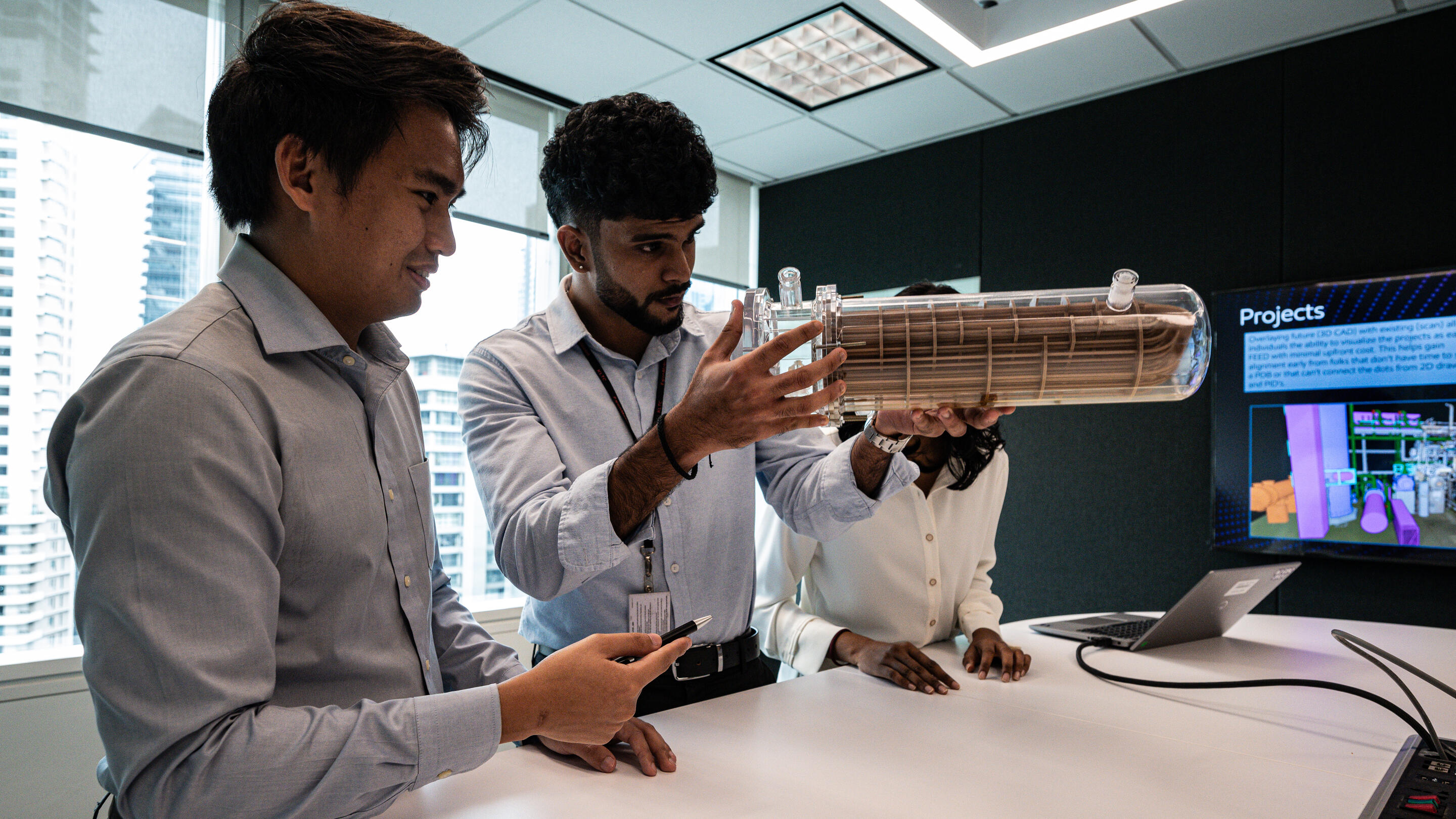

Advanced recycling works by breaking down plastic waste to its molecular building blocks, transforming it into raw materials that can be used to make virgin-quality plastic and other valuable new products. The process helps minimize contaminants and can accommodate mixed, multi-layer plastics.

In Southeast Asia, ExxonMobil is supporting the development of tailored models to address plastic waste – helping society to surpass the 12% recycling rate for plastic waste currently estimated in OECD Asian countries and helping to meet growing consumer demand for circular products.

Innovation in Indonesia

In November 2022, ExxonMobil signed a Memorandum of Understanding (MoU) with Indomobil Prima Energi and Plastic Energy in Indonesia. The MoU aims to assess the potential for large-scale implementation of advanced plastic recycling technology. The recycling capacity for this opportunity is expected to reach 100,000 metric tons a year over time, with a first phase potentially starting up in 2025.

With this advanced recycling agreement , Indonesia can help play a leading role in the world of plastic recycling.

Wai-Kong emphasized that the agreement aims to address plastic waste that might have otherwise ended up in landfill, incineration or the environment, with the waste instead being processed at a pyrolysis plant. The pyrolysis oil produced at the plant will then be transformed into raw materials that can be used to make virgin-quality plastic and other valuable new products at ExxonMobil’s chemical plant in Singapore.

Material recycling in Malaysia

A similar agreement to assess advanced plastic recycling opportunities was signed in Malaysia in late 2022 between ExxonMobil and PETRONAS Chemicals Group Berhad.

Through the MoU, the companies hope their collaboration will accelerate the transition into a circular economy for plastics in Malaysia through large-scale implementation of advanced plastic recycling technology.

In collaboration with the Malaysian Plastics Manufacturers Association and Scientex Berhad, ExxonMobil has jointly launched the Green Truck mobile recycling education program. The Green Truck visits schools in Malaysia to help educate children about the role of plastics in our everyday lives and the benefits of recycling. The program focuses on the importance of implementing the ‘3 Rs’ concept in everyday life: Reduce, Reuse, Recycle.

Creating a circular economy for plastics in Southeast Asia and around the world

ExxonMobil is also exploring advanced recycling opportunities in neighbouring countries, including Singapore, helping to accelerate a circular economy for plastics in Southeast Asia.

Meanwhile, ExxonMobil continues to collaborate with customers and brand owners to help meet their demand for certified-circular plastic products. Recently, the company made its first commercial sales of certified-circular plastics in Asia Pacific to Scientex for use in flexible food packaging.

By offering advanced recycling solutions, ExxonMobil is making it possible for a far broader range of plastic waste to be recycled. This puts us one step closer to a world where society can better capture the value of plastic waste.

Globally, ExxonMobil plans to increase its annual advanced recycling capacity to approximately 500,000 metric tons by year-end 2026. This would take place across multiple sites around the world, including in the U.S., Canada, Europe and Asia Pacific. In Texas, our Baytown advanced recycling facility is one of the largest advanced plastic waste recycling facilities in North America, with capacity to annually process 40,000 metric tons of plastic waste that might have otherwise ended up in landfill or incineration.

Technologies like advanced recycling can help to address plastic waste in Asia Pacific and create a circular economy – transforming plastic waste into new products that we use every day.

Asia Pacific region

Newsroom

Stay up to date with the latest news and information

Explore more

Faizah Mohd Noor: Cultivating careers and curiosity through STEM

3 min read

•

Digital minds, global solutions: KLTC’s virtual way of working

2 min read

•

Empowering the next generation through STEM education

4 min read

•

Global engineering talent in the heart of Malaysia

3 min read

•

Getting a headstart: Giving students a taste of real-world challenges

2 min read

•

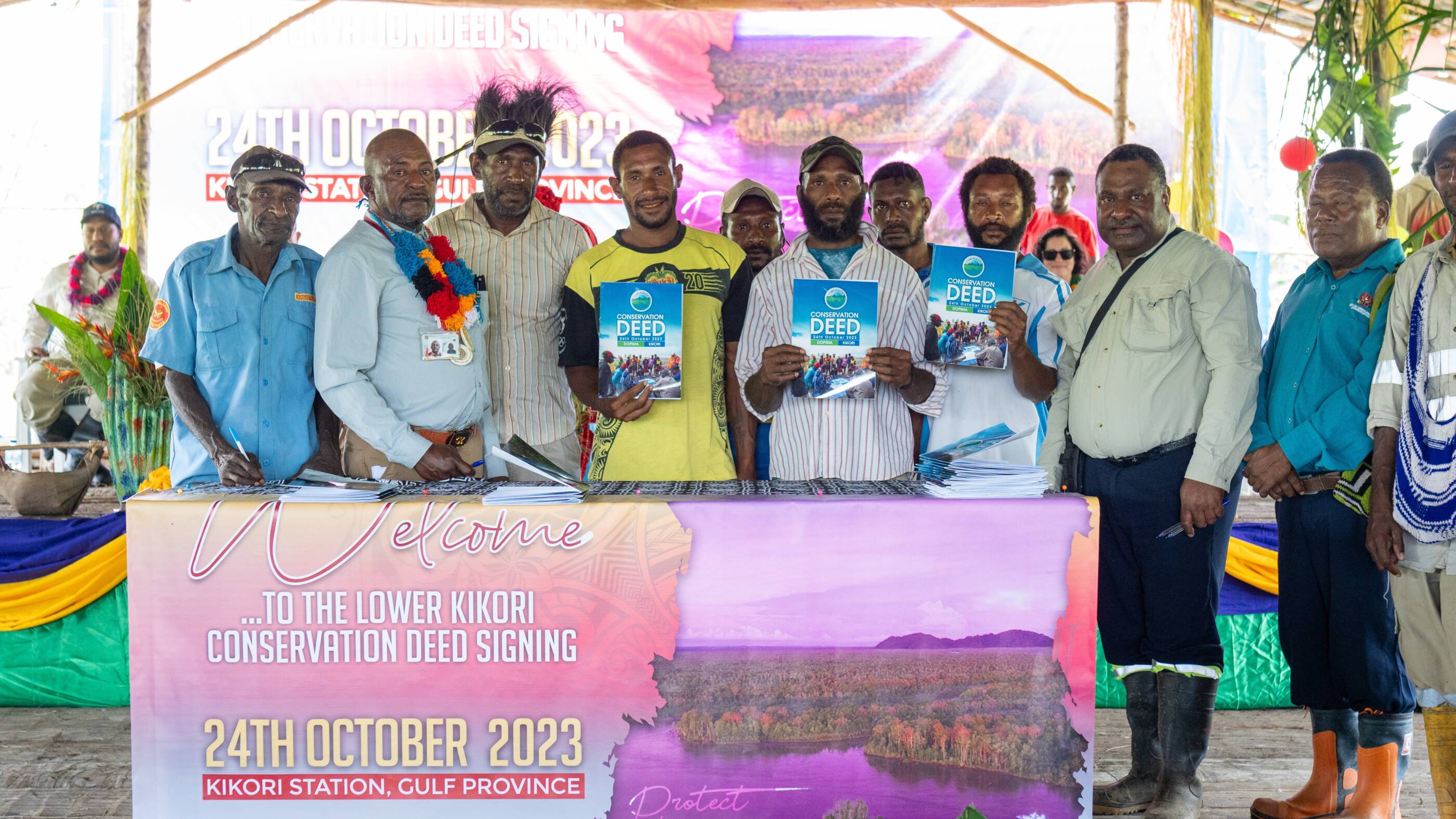

Papua New Guinea clans unite to conserve 20,000 hectares

2 min read

•