selected item

2 min read

•Co-processing: Making tomorrow’s fuel with today’s facilities

Key takeaways:

- Co-processing can accelerate the path to a lower-carbon future.

- This technology can use our existing infrastructure to produce more lower-emission fuels (LEFs).

- With policy support, co-processing can help meet rising demand for LEFs.

2 min read

•Most people understand the importance of electric vehicles to reducing transportation-related emissions. Equally important is reducing emissions from traditional vehicles that run on gasoline or diesel. That’s where lower-emission fuels (LEFs) like biofuels play an important role.

Demand for biofuels is expected to grow more than four-fold from 2021 to 2050. And during that same time period, biofuels are expected to be the primary transition fuel for aviation.1

One way ExxonMobil is helping to meet growing demand for LEFs is with our existing infrastructure.

How? Co-processing.

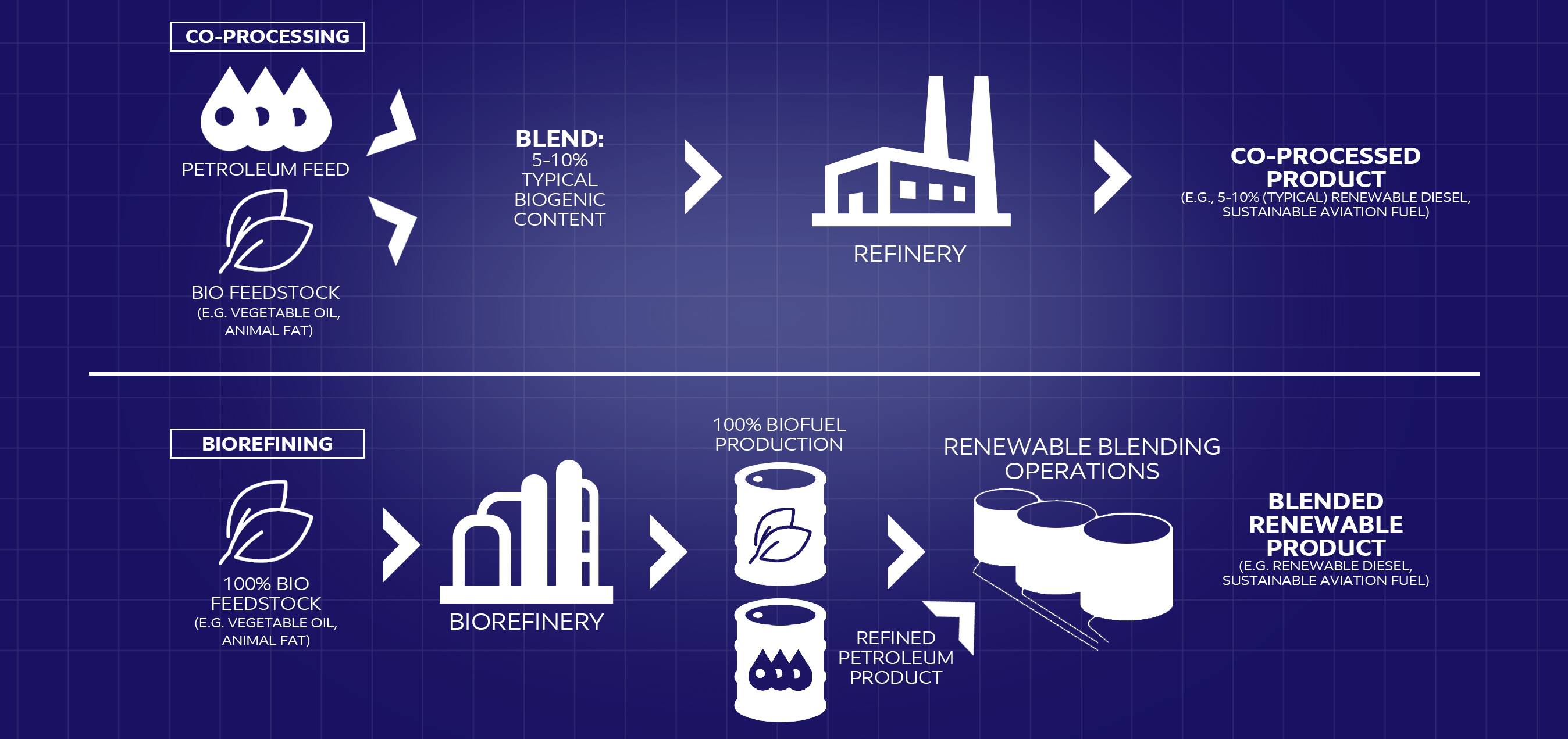

Co-processing makes transportation fuels with lower lifecycle greenhouse gas (GHG) emissions. It's a technology we have today that can quickly increase production of these lower-emission fuels for road transportation, aviation and marine shipping.

Unfortunately, current U.S. policies that are meant to incentivize biofuels production exclude co-processing, limiting the ability for U.S. refineries to play a part.

Policies that include co-processing could not only help meet today's energy needs, they could also help meet net-zero GHG emissions goals faster.

Co-processing to reduce emissions

The fuel derived from co-processing – whether gasoline, diesel or jet fuel – matches the quality and meets the same specifications as fuels produced at biorefineries.

Equally important, whether the LEFs are produced in an existing refinery via co-processing, or in a biorefinery and later blended with conventional fuels, the same biomass is helping reduce transportation lifecycle CO2 emissions.

Co-processing advantages

-

Speed

A faster way to increase the production of lower-emission fuels. -

Lower cost

May reduce the cost of reducing lifecycle GHG emissions. -

Reduced footprint

Can use an already-permitted industrial footprint. -

Scalability

Leverages existing, large industrial facilities, technology, logistics and experience. -

Competition

Levels the playing field for all biofuel production pathways.

Policy is imperative

Policies to advance LEFs should be technology neutral.

The Inflation Reduction Act created an uneven playing field by excluding co-processing from both the Sustainable Aviation Fuel (SAF) and Clean Fuel Production credits.

All fuel pathways can play a role, and policy support could help offset the added costs of production.

Policymakers hold the key to helping meet the growing demand for LEFs and advancing net-zero GHG emission goals.

Lower-emission fuels

Explore more