selected item

3 min read

•Greasing the wheels of Indian manufacturing

Key takeaways:

- We supply advanced lubricants and engineering services to Indian manufacturers across many sectors.

- We’re building a lubricant-manufacturing plant in Maharashtra with a capacity of 159,000 kiloliters of finished lubricants a year.

- The right lubricant can reduce machinery downtimes and boost savings.

3 min read

•India is aiming to become a global manufacturing powerhouse, so what can help ensure this growth doesn’t grind to a halt?

Manufacturing activity in India is surging as the country plays an increasing role in supplying to the world.

While this is helping to put India on track to become the world’s third-largest economy by 2030, manufacturing must continue to power ahead at a cracking pace to accelerate the nation’s growth.

This is why a key focus for the country has been expanding the nation’s domestic manufacturing capabilities in various sectors, as part of the government’s Aatmanirbhar Bharat (self-reliant India) mission.

ExxonMobil is supplying advanced Mobil-branded lubricants and engineering services to India’s manufacturers and is gearing up to do more.

In its first-ever greenfield investment in India, the company is building a lubricant-manufacturing plant in the country to help meet its growing lubricant demand.

The INR 900 crore (US$110 million) plant will have the capability to potentially manufacture 159,000 kiloliters of finished lubricants a year.

Construction is underway at the Maharashtra Industrial Development Corporation’s Isambe Industrial Area in Raigad, southeast of Mumbai. The plant is expected to begin operations at the end of 2025.

The right lubricant can be the difference between machinery running at peak performance or unexpectedly grinding to a halt. Discover below how ExxonMobil’s lubricants are helping Indian manufacturers work harder, for longer, saving lakhs in the process.

Explore more

Meet our STEM talent: Their mission is to drive meaningful change

2 min read

•

Our People and AI: Making the magic happen

2 min read

•

Taking Indian talent to the world stage

2 min read

•

Pragmatic and empowering: The force behind India’s energy story

2 min read

•

A to B: Turning Artificial Intelligence into Business Intelligence

3 min read

•

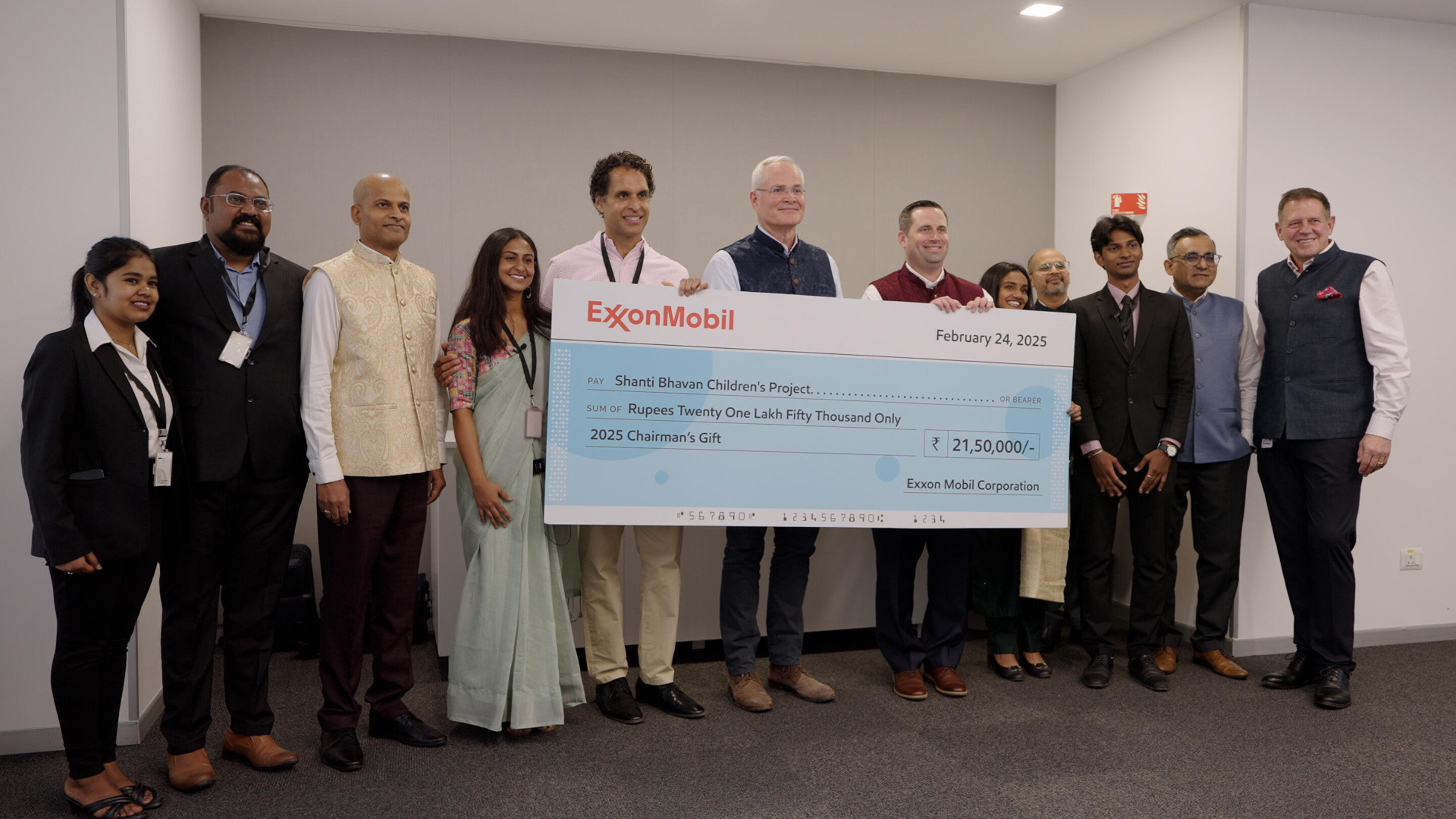

Changing lives with the power of education

5 min read

•