4 min read

•Research and development

4 min read

•Navigate to:

Our approach to R&D

For us, research and development starts with fundamental science and engineering. It is the foundation for our work to identify and advance new technologies that, once proven, could be deployed at a commercial scale with supportive policy in place.

We determine which research projects to advance based on a range of factors that include alignment with our competitive advantages and core capabilities. We also consider the benefits versus alternatives, the ability to scale, key partners, and the probability of commercial success.

As we work to advance carbon capture and storage, hydrogen, and lower-emission fuels opportunities, we are also investing in research and development aimed at next-generation, lower-emission solutions.

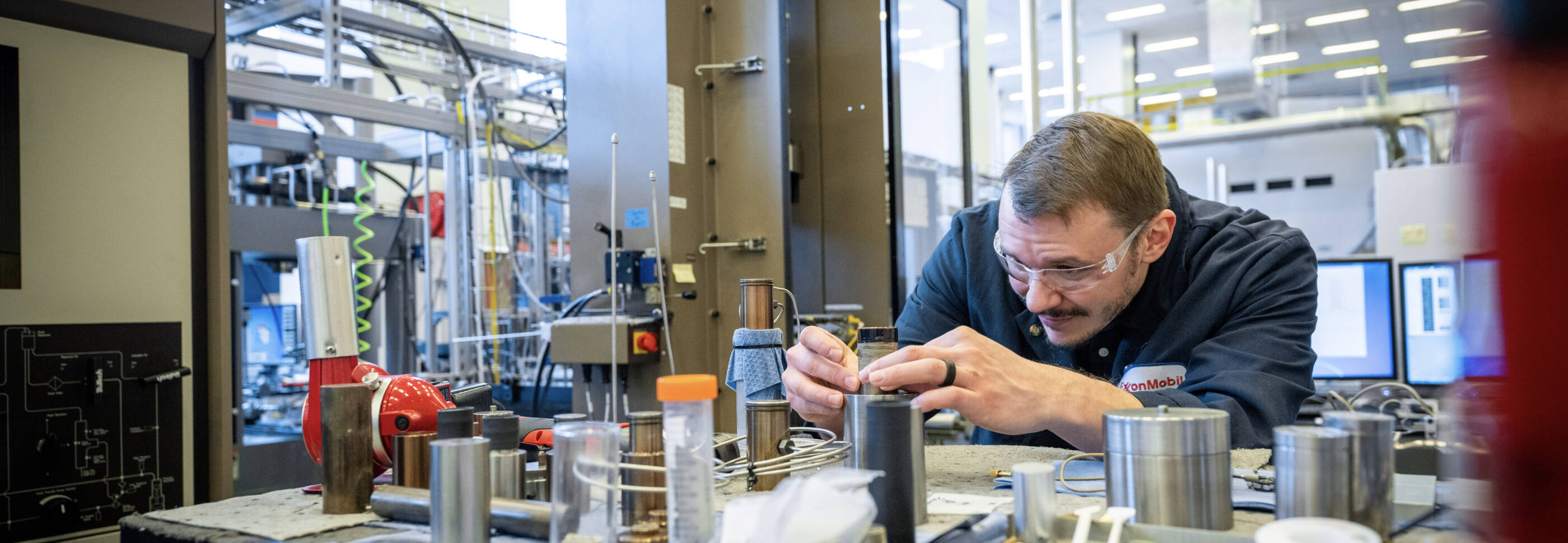

Thousands of scientists and engineers work at ExxonMobil, and more than 1,500 hold Ph.D.s. Those in R&D are exploring areas such as new catalytic and separation materials, novel low-energy process development and scale-up, advanced performance materials, and improved means of CO2 capture and storage.

Our scientists have written more than 1,000 peer-reviewed publications and received more than 10,000 patents since 2010. We also collaborate with more than 80 universities around the world, four energy centers, and several national laboratories.

These collaborations have increased knowledge in key areas important to the energy transition such as detection and modeling of fugitive methane emissions, CO2 capture and storage, process electrification, and energy systems models.

We also monitor emerging technologies to gain better insight into potential pathways of the energy transition. This can help us identify future research and development opportunities.

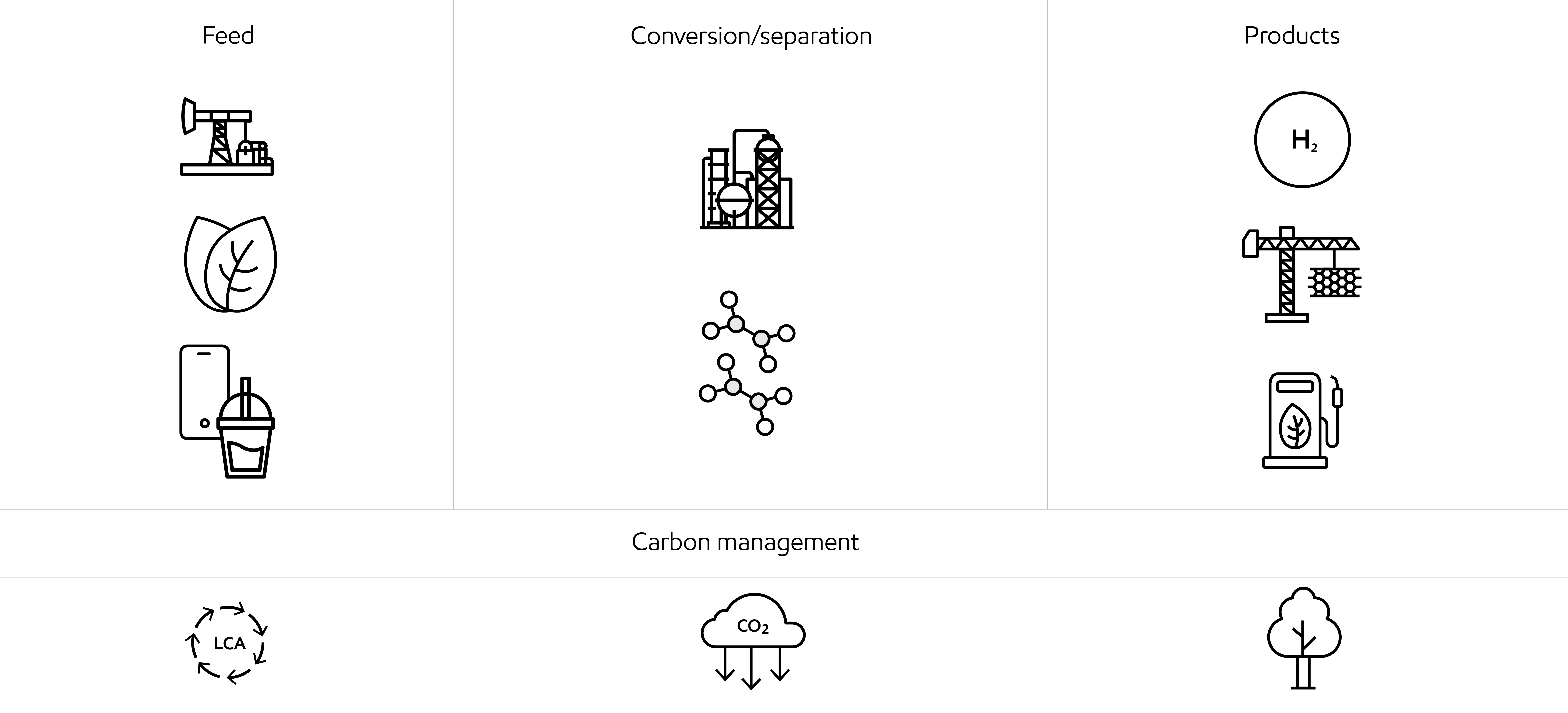

Innovating across our value chain

Feed

Biomass: We are working to expand the range of feedstocks to make biofuels, ranging from vegetable oils to cover crops and more. These have potential applications at our biofuels facilities, including our Strathcona renewable diesel plant and future advanced biofuel deployments.

Plastic waste: Our research to expand advanced (chemical) recycling focuses on plastics that are difficult to recycle mechanically. This technology would allow us to use a wider range of mixed plastic waste to make valuable raw materials safely, reliably, and economically at scale.

Methane detection: We are testing and deploying new technology to measure and reduce fugitive emissions from the natural gas we produce. Producing lower-emission-intensity natural gas also provides additional GHG benefits when it is used to support the production of low-carbon hydrogen.

Conversion/separation

New catalysts: We develop catalysts to make products such as performance materials and lower-emission fuels, including renewable fuels. For example, our dewaxing catalyst for renewable diesel gives a higher yield while requiring less hydrogen and improving the flow of diesel at low temperatures.

Low-energy separations: The sorting of molecules requires energy. This includes the isolation of hydrocarbons for use in the refining or chemical process. Increasing energy efficiency in this area can reduce emissions in manufacturing. Our scientists are building off years of research with university partners to identify ways to improve the scalability of this technology.1,2

GHG abatement and energy efficiency: We evaluate new technologies for our GHG roadmaps. This includes supporting future deployment of carbon capture, exploring opportunities for electrification and heat recovery, and pursuing the full range of efficiency improvements that may lower emissions.

Products

Hydrogen: We are developing advanced, lower-cost technology for production of low-carbon hydrogen at scale. We are also working with Zeeco, a leading combustion equipment manufacturer, on burners that allow industrial fuel switching to hydrogen and ammonia while controlling NOx emissions. In addition, we are testing and researching steel and other materials for pipelines to transport hydrogen and collaborating with the U.S. Department of Energy and industry organizations to evaluate safe and cost-effective hydrogen transport options. Progress in this area could help us grow the supply of hydrogen for a wide range of end users.3

Performance materials: Our R&D helps develop and deploy new thermosets, thermoplastics, and lubricants. Our advancements in these areas improve performance and allow the customer to use less energy and fewer materials. For example, our ProxximaTM thermoset resin systems, based on Nobel Prize-winning technology, provides advantages in automotive applications, infrastructure, coatings, and wind turbine blades.4 We are also studying additional opportunities for carbon materials where we see a significant opportunity in the market for synthetic graphite for EV battery anode materials and other applications.

Lower-emission fuels: Our continuing research in advanced biofuels could lead to improved longer-term solutions by converting bio-based feedstock into renewable fuels. For example, we have identified a new pathway for the production of sustainable aviation fuel (SAF) from renewable methanol, which can produce jet fuel with high selectivity and lead to reduced GHG emissions. In addition, we are leading the industry through an ASTM technical evaluation of this pathway to certify its use in aircraft.

Carbon management

Post-combustion carbon capture: We have a strategic alliance with Mitsubishi Heavy Industries (MHI) to deploy their CO2 capture technology as part of our end-to-end carbon capture and storage solution for industrial customers. This alliance also leverages our combined core capabilities in engineering and science to advance the carbon capture technology for improved performance and lower overall cost of CO2 capture.

We are working to develop next-generation carbonate fuel cell technology with FuelCell Energy for CO2 capture from industrial point sources. A project is underway at our Rotterdam refinery to validate fuel cell performance and lower the cost of CO2 avoidance in an industrial deployment. We are developing commercialization options as part of our Low Carbon Solutions portfolio.

Direct air capture (DAC): We believe there is potential for direct air capture to play an important role in addressing GHG emissions. With our in-house expertise and select partners, we plan to play a leading role in the development of this technology. We brought a DAC prototype demonstration unit online in early 2024. Our goal is to produce a lower-cost commercial platform at scale through rapid learning cycles.

Carbon storage: We continue to build upon our expertise to improve technologies required for the global scale-up of geologic CO2 storage. One example is our work with the Massachusetts Institute of Technology (MIT) to build fault permeability models to help manage and mitigate CO2 migration potential.5 We also worked with the University of Texas at Austin, the National Energy Technology Laboratory, and Brooklyn College and the Benjamin Levich Institute at City College, both part of City University of New York. In that collaboration, our laboratory simulations indicated that the pore-scale sealing of caprocks is maintained under geological CO2 storage conditions.6,7,8

Carbon offsets: We continue to evaluate potential opportunities for high quality carbon credits that remove CO2 from the atmosphere, either directly or indirectly, and durably store the carbon. Our research includes developing science-based approaches for measuring, reporting, and verifying carbon credits. Our work in carbon reduction and removal technologies may also help supply high-quality credits to markets.

Life-cycle assessment: We develop life-cycle assessments with multiple partners to compare different technology options. For example, we collaborated on a recent report for the Department of Energy that explored the costs and benefits of scaling up low-carbon hydrogen for hard to abate industries, including the life cycle carbon intensity of different alternatives. We have also worked with MIT Energy Initiative to develop the Sustainable Energy System Analysis Modeling Environment (SESAME) tool, which was used in the study. It can perform full life-cycle assessments and techno-economic analysis for complex technology pathways. These pathways range from primary energy sources to final products or services.9

Publications

Explore more

Rational and constructive policy

5 min read

•

Positioned for growth in a lower-emission future

8 min read

•

Growing Low Carbon Solutions

8 min read

•

Advancing Climate Solutions Executive Summary

6 min read

•

Driving reductions in methane emissions

6 min read

•

Our risk management approach

4 min read

•FOOTNOTES:

- K. Thompson, R. Mathias, D. Kim, J. Kim, N. Rangnekar, J. Johnson, S. Hoy, I. Bechis, A. Tarzia, K. Jelfs, B. McCool, A. Livingston, R. Lively, M. Finn, N-Aryl-linked spirocyclic polymers for membrane separations of complex hydrocarbon mixtures, Science 369 (6501) (2020) 310-315.

- Siyao Li, Ruijiao Dong, Valentina-Elena Musteata, Jihoon Kim, Neel D. Rangnekar, J. R. Johnson, Bennett D. Marshall, Stefan Chisca, Jia Xu, Scott Hoy, Benjamin A. McCool, Suzana P. Nunes, Zhiwei Jiang, Andrew G. Livingston, Hydrophobic polyamide nanofilms provide rapid transport for crude oil separation, Science 377 (6614) (2022) 1555-1561.

- "HyBlend: Opportunities for Hydrogen Blending in Natural Gas Pipelines" | Department of Energy: https://www.energy.gov/eere/fuelcells/hyblend-opportunities-hydrogen-blending-natural-gas-pipelines.

- Targeting global markets in both the coatings and composites industries: In coatings the focus is on corrosion protection of vessels (e.g., tanks, ships, and railcars) and insulation (e.g., subsea pipes and equipment) applications. Within composite materials (i.e., materials containing glass or carbon fiber) the focus in on infrastructure, wind energy, and mobility sectors. Examples include replacing steel rebar in flatwork applications, replacing epoxy in wind turbines, and structural support in hydrogen tanks, EV battery casings, and other transportation components.

- L. Saló-Salgado, S. Davis, R. Juanes; Fault permeability from stochastic modeling of clay smears. Geology 2022; 51 (1): 91–95. doi: https://doi.org/10.1130/G50739.1.

- Awad, M. M. and D. N. Espinoza (2024). "Mudrock wettability at pressure and temperature conditions for CO2 geological storage." International Journal of Greenhouse Gas Control 135: 104160.

- Tapriyal, D., Haeri, F., Crandall, D., Horn, W., Lun, L., Lee, A., Goodman, A. “CO2 wetting properties on reservoir caprock conducted at conditions targeted for commercial scale CO2 storage.” Geophysical Research Letters, 51, e2024GL109123 (2024) doi: https://doi.org/10.1029/2024GL109123.

- Camargo, A. P., Jusufi, A., Lee, A., Koplik, J., Morris, J. (2024). “Water and Carbon Dioxide Capillary Bridges in Nanoscale Slit Pores: Effects of Temperature, Pressure, and Salt Concentration on the Water Contact Angle.” Langmuir, 40 (35), pp. 18439–18450.

- E. Gencer, S. Torkamani, I. Miller, T. Wu, F. O’Sullivan, Sustainable energy system analysis modeling environment: analyzing life-cycle emissions of the energy transition, Applied Energy 277 (2020) 115550. doi: https://doi.org/10.1016/j.apenergy.2020.115550.

FORWARD-LOOKING STATEMENT WARNING

Images or statements of future ambitions, aims, aspirations, plans, goals, events, projects, projections, opportunities, expectations, performance, or conditions in the publications, including plans to reduce, abate, avoid or enable avoidance of emissions or reduce emissions intensity, sensitivity analyses, expectations, estimates, the development of future technologies, business plans, and sustainability efforts are dependent on future market factors, such as customer demand, continued technological progress, stable policy support and timely rule-making or continuation of government incentives and funding, and represent forward-looking statements. Similarly, emission-reduction roadmaps to drive toward net zero and similar roadmaps for emerging technologies and markets, and water management roadmaps to reduce freshwater intake and/or manage disposal, are forward-looking statements. These statements are not guarantees of future corporate, market or industry performance or outcomes for ExxonMobil or society and are subject to numerous risks and uncertainties, many of which are beyond our control or are even unknown.

Actual future results, including the achievement of ambitions to reach Scope 1 and 2 net zero from operated assets by 2050, to reach Scope 1 and 2 net zero in heritage Permian Basin unconventional operated assets by 2030, and in Pioneer Permian assets by 2035, to eliminate routine flaring in-line with World Bank Zero Routine Flaring, to reach near zero methane emissions from operated assets and other methane initiatives to meet ExxonMobil’s greenhouse gas emission reduction plans and goals, divestment and start-up plans, and associated project plans as well as technology advances, including in the timing and outcome of projects to capture, transport and store CO2, produce hydrogen and ammonia, produce lower-emission fuels, produce ProxximaTM systems, produce carbon materials, produce lithium, and use plastic waste as feedstock for advanced recycling; future debt levels and credit ratings; business and project plans, timing, costs, capacities and profitability; resource recoveries and production rates; planned Denbury and Pioneer integrated benefits; obtain data on detection, measurement and quantification of emissions including reporting of that data or updates to previous estimates and progress in sustainability focus areas could vary depending on a number of factors, including global or regional changes in oil, gas, petrochemicals, or feedstock prices, differentials, seasonal fluctuations, or other market or economic conditions affecting the oil, gas, and petrochemical industries and the demand for our products; new market products and services; future cash flows; our ability to execute operational objectives on a timely and successful basis; the ability to realize efficiencies within and across our business lines; new or changing government policies for lower carbon and new market investment opportunities, or policies limiting the attractiveness of investments such as European taxes on energy and unequal support for different methods of carbon capture; developments or changes in local, national, or international treaties, laws, regulations, taxes, trade sanctions, trade tariffs, and incentives affecting our business, including those related to greenhouse gas emissions, plastics, carbon storage and carbon costs; timely granting of governmental permits and certifications; uncertain impacts of deregulation on the legal and regulatory environment; evolving reporting standards for these topics and evolving measurement standards for reported data; trade patterns and the development and enforcement of local, national and regional mandates; unforeseen technical or operational difficulties; the outcome of research efforts and future technology developments, including the ability to scale projects and technologies such as electrification of operations, advanced recycling, carbon capture and storage, hydrogen and ammonia production, ProxximaTM systems, carbon materials or direct lithium extraction on a commercially competitive basis; the development and competitiveness of alternative energy and emission reduction technologies; unforeseen technical or operating difficulties, including the need for unplanned maintenance; availability of feedstocks for lower-emission fuels, hydrogen, or advanced recycling; changes in the relative energy mix across activities and geographies; the actions of co-venturers competitors; changes in regional and global economic growth rates and consumer preferences including willingness and ability to pay for reduced emissions products; actions taken by governments and consumers resulting from a pandemic; changes in population growth, economic development or migration patterns; timely completion of construction projects; war, civil unrest, attacks against the Company or industry, and other political or security disturbances, including disruption of land or sea transportation routes; decoupling of economies, realignment of global trade and supply chain networks, and disruptions in military alliances; and other factors discussed here and in Item 1A. Risk Factors of our Annual Report on Form 10-K and under the heading “Factors affecting future results” available under the “Earnings” tab through the “Investors” page of our website at www.exxonmobil.com. The Advancing Climate Solutions Report includes 2024 greenhouse gas emissions performance data as of March 1, 2025, and Scope 3 Category 11 estimates for full year 2024 as of February 19, 2025. The greenhouse gas intensity and greenhouse gas emission estimates include Scope 2 market-based emissions. The Sustainability Report, the Advancing Climate Solutions Report, and corresponding Executive Summaries were issued on April 30, 2025. The content and data referenced in these publications focus primarily on our operations from Jan. 1, 2024 – Dec. 31, 2024, unless otherwise indicated. Tables on our “Metrics and data” page were updated to reflect full year 2024 data. Information regarding some known events or activities in 2025 and historical initiatives from prior years are also included. No party should place undue reliance on these forward-looking statements, which speak only as of the dates of these publications. All forward-looking statements are based on management’s knowledge and reasonable expectations at the time of publication. ExxonMobil assumes no duty to update these statements or materials as of any future date, and neither future distribution of this material nor the continued availability of this material in archive form on our website should be deemed to constitute an update or re-affirmation of these figures or statements as of any future date. Any future update will be provided only through a public disclosure indicating that fact.

See “ABOUT THE ADVANCING CLIMATE SOLUTIONS AND SUSTAINABILITY REPORTS” at the end of this document for additional information on these reports and the use of non-GAAP and other financial measures.

ABOUT THE ADVANCING CLIMATE SOLUTIONS AND SUSTAINABILITY REPORTS

The Advancing Climate Solutions Report contains terms used by the TCFD, as well as information about how the disclosures in this report are consistent with the recommendations of the TCFD. In doing so, ExxonMobil is not obligating itself to use any terms in the way defined by the TCFD or any other party, nor is it obligating itself to comply with any specific recommendation of the TCFD or to provide any specific disclosure. For example, with respect to the term “material,” individual companies are best suited to determine what information is material, under the long-standing U.S. Supreme Court definition, and whether to include this information in U.S. Securities and Exchange Act filings. In addition, the ISSB is evaluating standards that provide their interpretation of TCFD which may or may not be consistent with the current TCFD recommendations. The Sustainability Report and Advancing Climate Solutions Report are each a voluntary disclosure and are not designed to fulfill any U.S., foreign, or third-party required reporting framework.

Forward-looking and other statements regarding environmental and other sustainability efforts and aspirations are not intended to communicate any material investment information under the laws of the United States or represent that these are required disclosures. These publications are not intended to imply that ExxonMobil has access to any significant non-public insights on future events that the reader could not independently research. In addition, historical, current, and forward-looking environmental and other sustainability-related statements may be based on standards for measuring progress that are still developing, internal controls and processes that continue to evolve, and assumptions that are subject to change in the future, including future laws and rulemaking. Forward-looking and other statements regarding environmental and other sustainability efforts and aspirations are for informational purposes only and are not intended as an advertisement for ExxonMobil’s equity, debt, businesses, products, or services and the reader is specifically notified that any investor-requested disclosure or future required disclosure is not and should not be construed as an inducement for the reader to purchase any product or services. The statements and analysis in these publications represent a good faith effort by the Company to address these investor requests despite significant unknown variables and, at times, inconsistent market data, government policy signals, and calculation, methodologies, or reporting standards.

Actions needed to advance ExxonMobil’s 2030 greenhouse gas emission-reductions plans are incorporated into its medium-term business plans, which are updated annually. The reference case for planning beyond 2030 is based on the Company’s Global Outlook research and publication. The Global Outlook is reflective of the existing global policy environment and an assumption of increasing policy stringency and technology improvement to 2050. However, the Global Outlook does not attempt to project the degree of required future policy and technology advancement and deployment for the world, or ExxonMobil, to meet net zero by 2050. As future policies and technology advancements emerge, they will be incorporated into the GIobal Outlook, and the Company’s business plans will be updated as appropriate. References to projects or opportunities may not reflect investment decisions made by the corporation or its affiliates. Individual projects or opportunities may advance based on a number of factors, including availability of stable and supportive policy, permitting, technological advancement for cost-effective abatement, insights from the Company planning process, and alignment with our partners and other stakeholders. Capital investment guidance in lower-emission and other new investments is based on our corporate plan; however, actual investment levels will be subject to the availability of the opportunity set, stable public policy support, other factors, and focused on returns.

Energy demand modeling aims to replicate system dynamics of the global energy system, requiring simplifications. The reference to any scenario or any pathway for an energy transition, including any potential net-zero scenario, does not imply ExxonMobil views any particular scenario as likely to occur. In addition, energy demand scenarios require assumptions on a variety of parameters. As such, the outcome of any given scenario using an energy demand model comes with a high degree of uncertainty. For example, the IEA describes its NZE scenario as extremely challenging, requiring unprecedented innovation, unprecedented international cooperation, and sustained support and participation from consumers, with steeper reductions required each year since the scenario’s initial release. Third-party scenarios discussed in these reports reflect the modeling assumptions and outputs of their respective authors, not ExxonMobil, and their use or inclusion herein is not an endorsement by ExxonMobil of their underlying assumptions, likelihood, or probability. Investment decisions are made on the basis of ExxonMobil’s separate planning process but may be secondarily tested for robustness or resiliency against different assumptions, including against various scenarios. These reports contain information from third parties. ExxonMobil makes no representation or warranty as to the third-party information. Where necessary, ExxonMobil received permission to cite third-party sources, but the information and data remain under the control and direction of the third parties. ExxonMobil has also provided links in this report to third-party websites for ease of reference. ExxonMobil’s use of the third-party content is not an endorsement or adoption of such information.

ExxonMobil reported emissions, including reductions and avoidance performance data, are based on a combination of measured and estimated data. We assess our performance to support continuous improvement throughout the organization using our Environmental Performance Indicator (EPI) manual. The reporting guidelines and indicators in the Ipieca, the American Petroleum Institute (API), the International Association of Oil and Gas Producers Sustainability Reporting Guidance for the Oil and Gas Industry (4th edition, 2020, revised February 2023) and key chapters of the GHG Protocol inform the EPI and the selection of the data reported. Emissions reported are estimates only, and performance data depends on variations in processes and operations, the availability of sufficient data, the quality of those data and methodology used for measurement and estimation. Emissions data is subject to change as methods, data quality, and technology improvements occur, and changes to performance data may be updated. Emissions, reductions, abatements and enabled avoidance estimates for non-ExxonMobil operated facilities are included in the equity data and similarly may be updated as changes in the performance data are reported. ExxonMobil’s plans to reduce emissions are good-faith efforts based on current relevant data and methodology, which could be changed or refined. ExxonMobil works to continuously improve its approach to estimate, detect, measure, and address emissions. ExxonMobil actively engages with industry, including API and Ipieca, to improve emission factors and methodologies, including measurements and estimates.

Any reference to ExxonMobil’s support of, work with, or collaboration with a third-party organization within these publications do not constitute or imply an endorsement by ExxonMobil of any or all of the positions or activities of such organization. ExxonMobil participates, along with other companies, institutes, universities and other organizations, in various initiatives, campaigns, projects, groups, trade organizations, and other collaborations among industry and through organizations like the United Nations that express various ambitions, aspirations and goals related to climate change, emissions, sustainability, and the energy transition. ExxonMobil’s participation or membership in such collaborations is not a promise or guarantee that ExxonMobil’s individual ambitions, future performance or policies will align with the collective ambitions of the organizations or the individual ambitions of other participants, all of which are subject to a variety of uncertainties and other factors, many of which may be beyond ExxonMobil’s control, including government regulation, availability and cost-effectiveness of technologies, and market forces and other risks and uncertainties. Such third parties’ statements of collaborative or individual ambitions and goals frequently diverge from ExxonMobil’s own ambitions, plans, goals, and commitments. ExxonMobil will continue to make independent decisions regarding the operation of its business, including its climate-related and sustainability-related ambitions, plans, goals, commitments, and investments. ExxonMobil’s future ambitions, goals and commitments reflect ExxonMobil’s current plans, and ExxonMobil may unilaterally change them for various reasons, including adoption of new reporting standards or practices, market conditions; changes in its portfolio; and financial, operational, regulatory, reputational, legal and other factors.

References to “resources,” “resource base,” “recoverable resources” and similar terms refer to the total remaining estimated quantities of oil and natural gas that are expected to be ultimately recoverable. The resource base includes quantities of oil and natural gas classified as proved reserves, as well as quantities that are not yet classified as proved reserves, but that are expected to be ultimately recoverable. The term “resource base” is not intended to correspond to SEC definitions such as “probable” or “possible” reserves. For additional information, see the “Frequently Used Terms” on the Investors page of the Company’s website at www.exxonmobil.com under the header “Modeling Toolkit.” References to “oil” and “gas” include crude, natural gas liquids, bitumen, synthetic oil, and natural gas. The term “project” as used in these publications can refer to a variety of different activities and does not necessarily have the same meaning as in any government payment transparency reports.

Exxon Mobil Corporation has numerous affiliates, many with names that include ExxonMobil, Exxon, Mobil, Esso, and XTO. For convenience and simplicity, those terms and terms such as “Corporation,” “company,” “our,” “we,” and “its” are sometimes used as abbreviated references to one or more specific affiliates or affiliate groups. Abbreviated references describing global or regional operational organizations, and global or regional business lines are also sometimes used for convenience and simplicity. Nothing contained herein is intended to override the corporate separateness of affiliated companies. Exxon Mobil Corporation’s goals do not guarantee any action or future performance by its affiliates or Exxon Mobil Corporation’s responsibility for those affiliates’ actions and future performance, each affiliate of which manages its own affairs. For convenience and simplicity, words like venture, joint venture, partnership, co-venturer and partner are used to indicate business relationships involving common activities and interests, and those words may not indicate precise legal relationships. These publications cover Exxon Mobil Corporation’s owned and operated businesses and do not address the performance or operations of our suppliers, contractors or partners unless otherwise noted. In the case of certain joint ventures for which ExxonMobil is the operator, we often exercise influence but not control. Thus, the governance, processes, management and strategy of these joint ventures may differ from those in these reports. At the time of publication, ExxonMobil has completed the acquisitions of Denbury Inc. and Pioneer Natural Resources Company. These reports and the data therein do not speak of these companies’ pre-acquisition governance, risk management, strategy approaches, or emissions or sustainability performance unless specifically referenced.

These reports or any material therein are not to be used or reproduced without the permission of Exxon Mobil Corporation. All rights reserved.

SUPPLEMENTAL INFORMATION FOR NON-GAAP AND OTHER MEASURES

The Positioned for Growth in a Lower-Emission Future section of the Advancing Climate Solutions Report mentions modeled operating cash flow in comparing different businesses over time in a future scenario. Historic operating cash flow is defined as net income, plus depreciation, depletion and amortization for consolidated and equity companies, plus noncash adjustments related to asset retirement obligations plus proceeds from asset sales. The Company’s long-term portfolio modeling estimates operating cash flow as revenue or margins less cash expenses, taxes and abandonment expenditures plus proceeds from asset sales before portfolio capital expenditures. The Company believes this measure can be helpful in assessing the resiliency of the business to generate cash from different potential future markets. The performance data presented in the Advancing Climate Solutions Report and Sustainability Report, including on emissions, is not financial data and is not GAAP data.