selected item

3 min read

•Rock on, Jen! How a geoscientist looks for lithium

Key takeaways:

- Lithium project underway in Arkansas

- We’re reaching lithium deep underground

- Geoscience is key to the project’s success

3 min read

•Like many science-loving kids, Jennifer Anthony had a rock collection growing up.

Today, Jen’s still into rocks. She’s one of the geoscientists supporting ExxonMobil’s landmark plan to produce lithium for electric vehicles, by pulling it out of salty brine water in limestone rock thousands of feet below the ground in southwest Arkansas.

Jen – who has a master’s in geoscience from Penn State and is mom to an 8-year-old daughter – has worked for ExxonMobil for nearly 20 years. During her career, she’s supported oil and natural gas drilling projects all over the world, including in Guyana, Angola and Vietnam.

Now she’s focused on Arkansas, where we’re ramping up our plan to become a major supplier of lithium for electric vehicles.

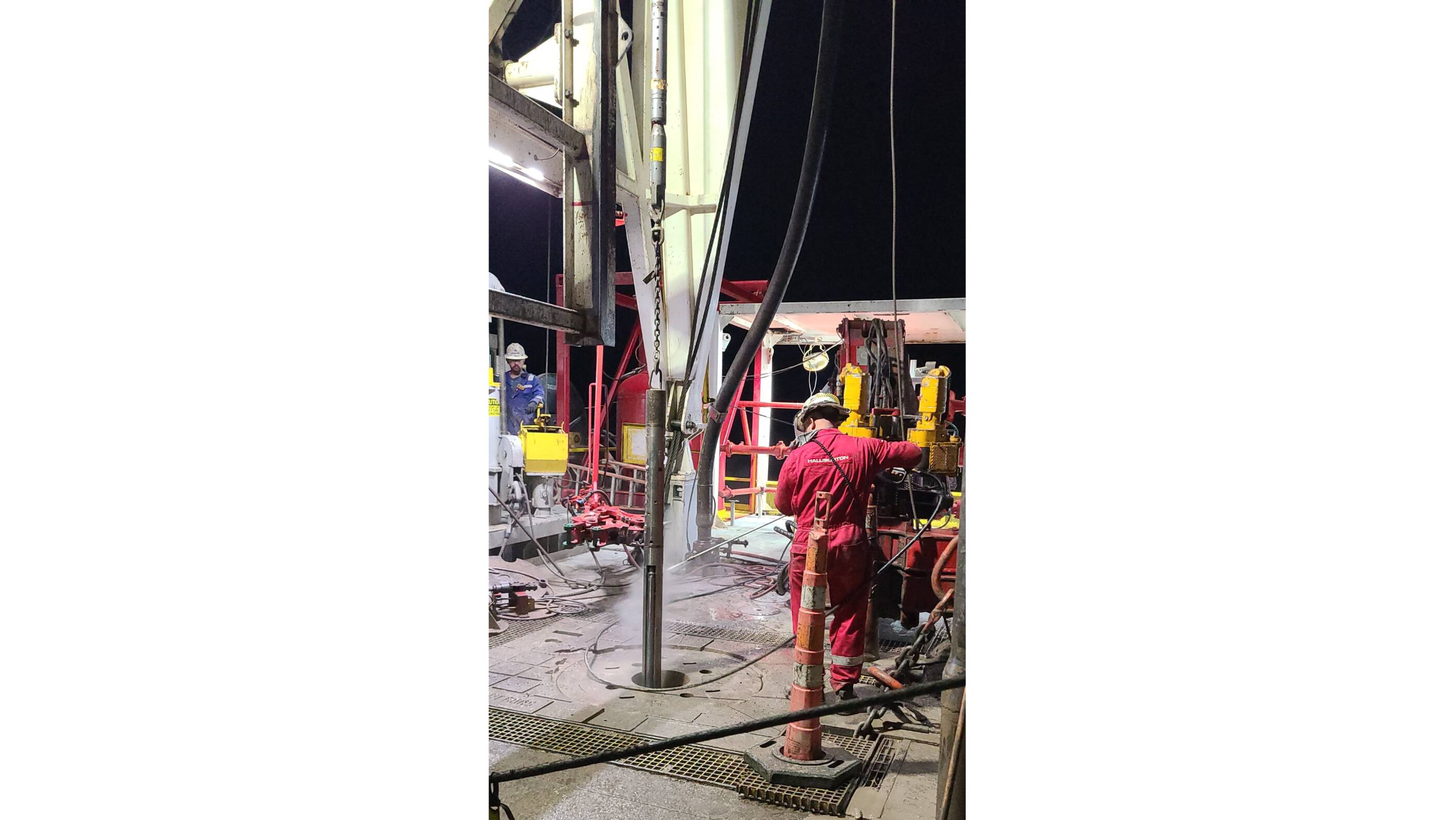

Our lithium work is moving fast. Just three months after we announced our lithium plan, we’ve drilled several appraisal wells to sample brine for testing – and produced small batches of battery-grade lithium. “Our goal is to gather information to help produce the resource most effectively,” Jen said.

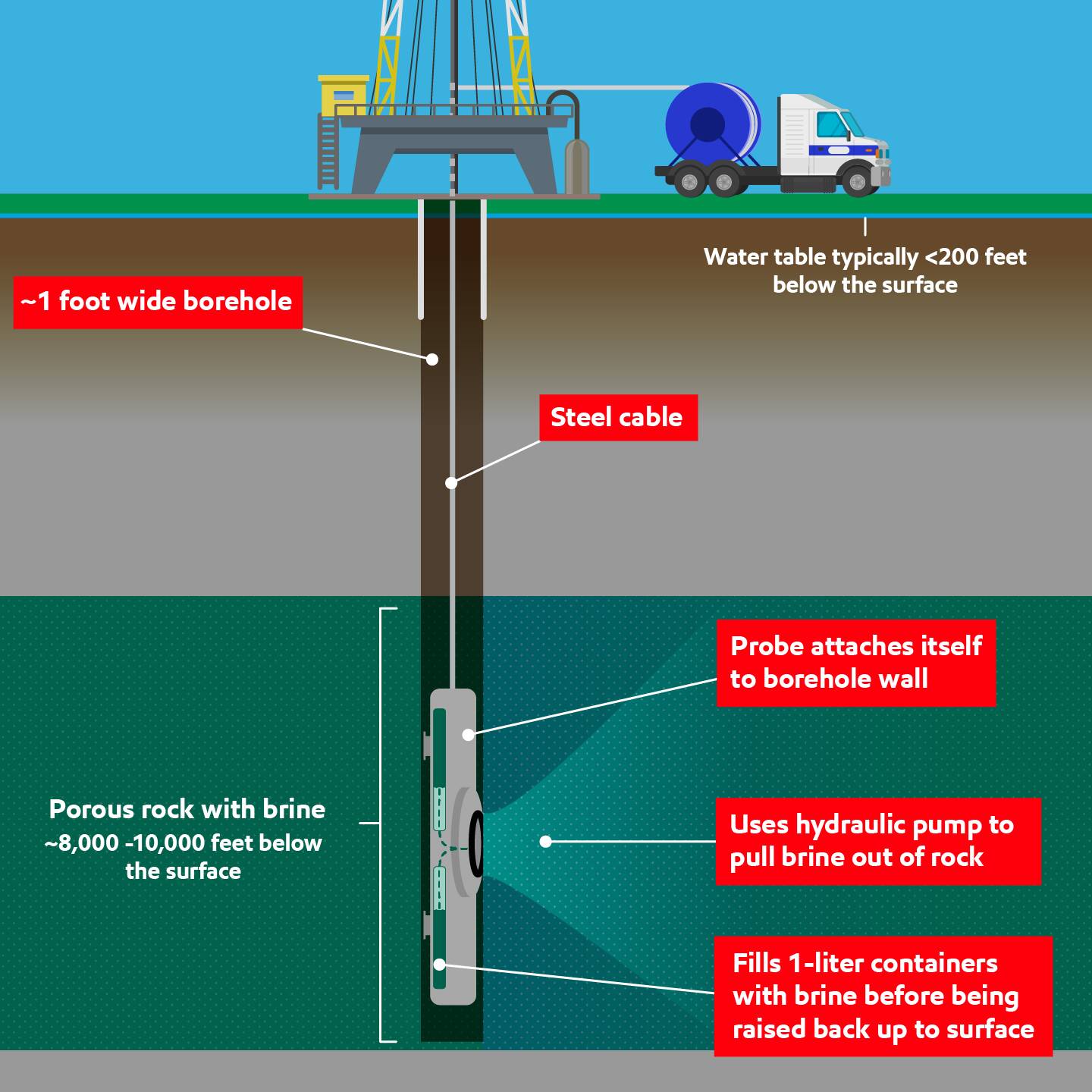

Simplified schematic to illustrate downhole fluid sampling. Not to scale.

Looking for lithium 10,000 feet down

How do Jen and her colleagues do it? They use advanced technologies to “look” into limestone thousands of feet below the ground. Much like a pumice stone, the rock is porous, and the pores are filled with salty brine that contains lithium.

“We’re looking for the sections of rock that are most porous, because these areas are more likely to hold a lot of brine,” Jen said. “We’re also looking for areas where the brine might have a high concentration of lithium. That’s where we want to take our samples.”

How do we get samples of liquid trapped in rock more than a mile underground?

- First, we drill a hole (about a foot wide), then lower a probe into the hole via a steel cable. The probe is equipped with advanced electronics that can send and receive information back to our people above ground.

- Once the probe reaches the desired depth (8,000-10,000 feet), it attaches itself to the wellbore wall, and uses a hydraulic pump to suck the brine out of the rock, filling several one-liter steel containers contained inside the probe.

- We then pull the probe up to the surface and the brine-filled containers are sent on to the lab for testing. Scroll down to see some photos of this work in action.

It sounds complicated, and it is. The work requires geoscientists like Jen, but also reservoir engineers, drilling engineers, well logging engineers, petrophysicists, operations geologists, and geochemists. But it’s also very similar to the types of work we’ve been doing for decades in oil and natural gas.

Rocking out, even on vacation

Ultimately, we plan to bring large volumes of brine to the surface, separate the lithium, and inject the brine back underground. Production is expected to begin in 2027. By 2030, we hope to make enough to support the production of about 1 million electric vehicles.

Jen says she’s enjoying putting her geology skills to use in a different way. “It’s great to be able to apply our skills to a new product, one that will help the energy transition,” she said.

When asked if she pursues her love of rocks outside of working hours, Jen smiled and said, “Well, I’m about to take a vacation…”

Her destination? The Grand Canyon.

Explore more

Got 2 minutes? See how we’re turning brine into battery-grade lithium

2 min read

•

Expert spotlight: Stephanie Lollar - a “landman” pivots to lithium

3 min read

•

ExxonMobil and EV battery maker SK On sign MOU regarding U.S. produced Mobil™ Lithium

2 min read

•

Charging into the lithium business

3 min read

•Newsroom

Stay up to date with the latest news and information