3 min read

•Taking training into a new reality

3 min read

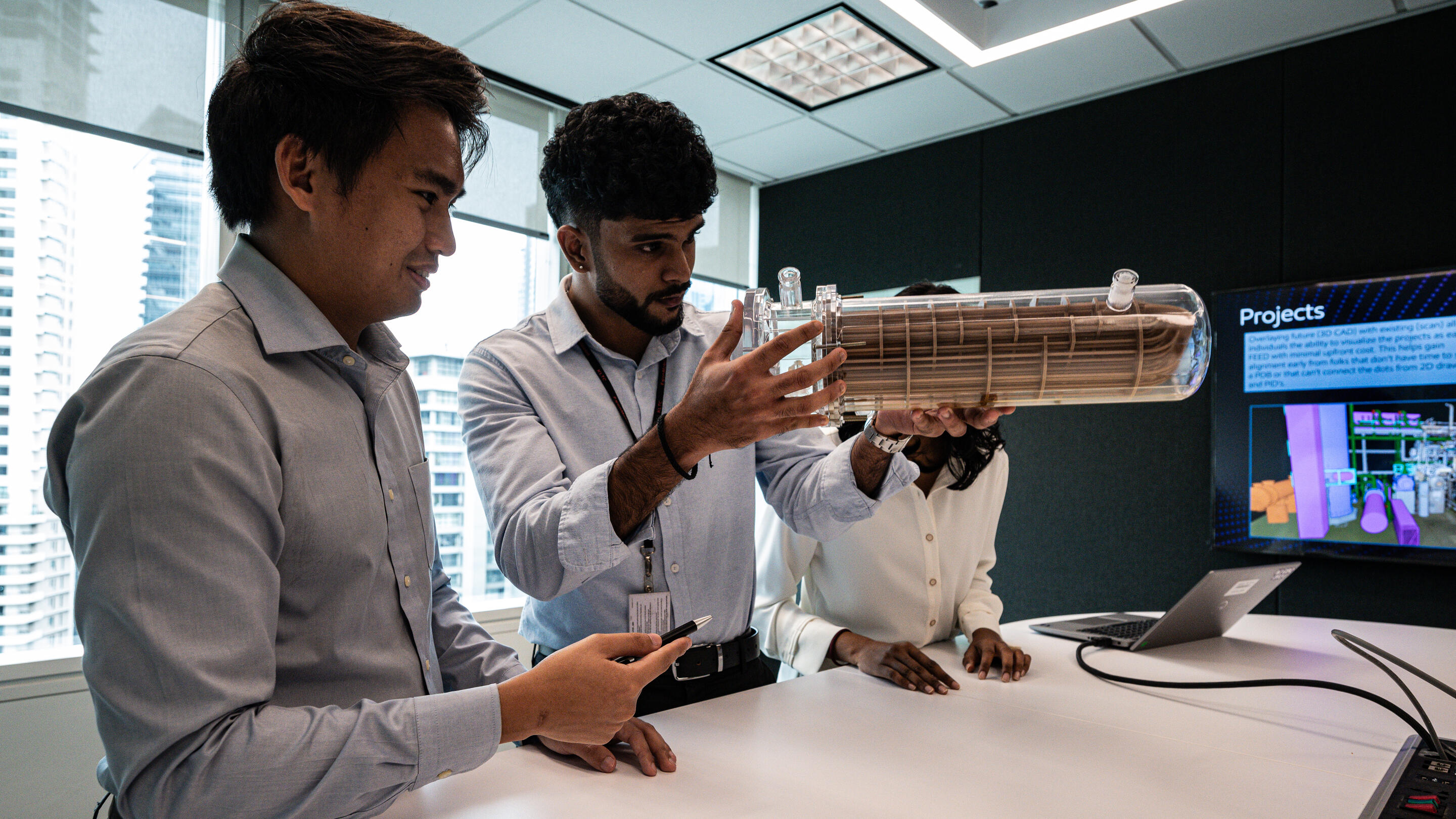

•Students from the Institute of Technical Education (ITE) colleges across Singapore are using virtual reality (VR) and augmented reality (AR), known together as mixed reality, to train, prepare and adapt to a rapidly evolving energy industry. These mixed reality training centres are sponsored by ExxonMobil.

Chemical Process Technology Lecturer Yam Weng Fatt from ITE College East said this technology had had a positive impact on learning.

“The VR simulator is a great gamification approach to engage learners. It infuses integrative learning on process unit operations that are impractical to demonstrate in a classroom,” Yam said.

“With this training, students can see the facilities and tools right in front of them. You can simulate operations, and it’s so life-like that you can even practise turning valves or use tools,” said ExxonMobil Singapore Refinery Process Manager Neo Ee Ee.

This technology has also changed the way students and workers understand and learn from their training, transforming learning from a passive to an active experience.

Historically, training has been carried out in two ways: either through learning via books and classes, a safe process which could leave people unprepared for real-life scenarios; or through on-the-job, live training, which can be riskier and costlier but exposes workers to more complex situations.

VR and AR offer a third path, allowing people to experience these real-life scenarios in an immersive, yet safe, environment.

VR training also appears to be more effective, with people retaining more information compared to traditional learning methods. Students also seem to learn more thoroughly, understanding the process better.

Another benefit of training with VR is that people can build up experience doing complex work tasks without having to stop operations or put lives at risk. This was seen recently at ExxonMobil’s manufacturing complex in Singapore.

“We created a VR simulation training program to help our Project and Maintenance crew get familiar with the complex work sequences they needed to carry out on a tower 150 meters above ground,” Neo said.

Singapore is currently one of the world’s leading research powerhouses in the use of AR for manufacturing and industrial processes.

Asia Pacific region

Newsroom

Stay up to date with the latest news and information

Explore more

Faizah Mohd Noor: Cultivating careers and curiosity through STEM

3 min read

•

Digital minds, global solutions: KLTC’s virtual way of working

2 min read

•

Empowering the next generation through STEM education

4 min read

•

Global engineering talent in the heart of Malaysia

3 min read

•

Getting a headstart: Giving students a taste of real-world challenges

2 min read

•

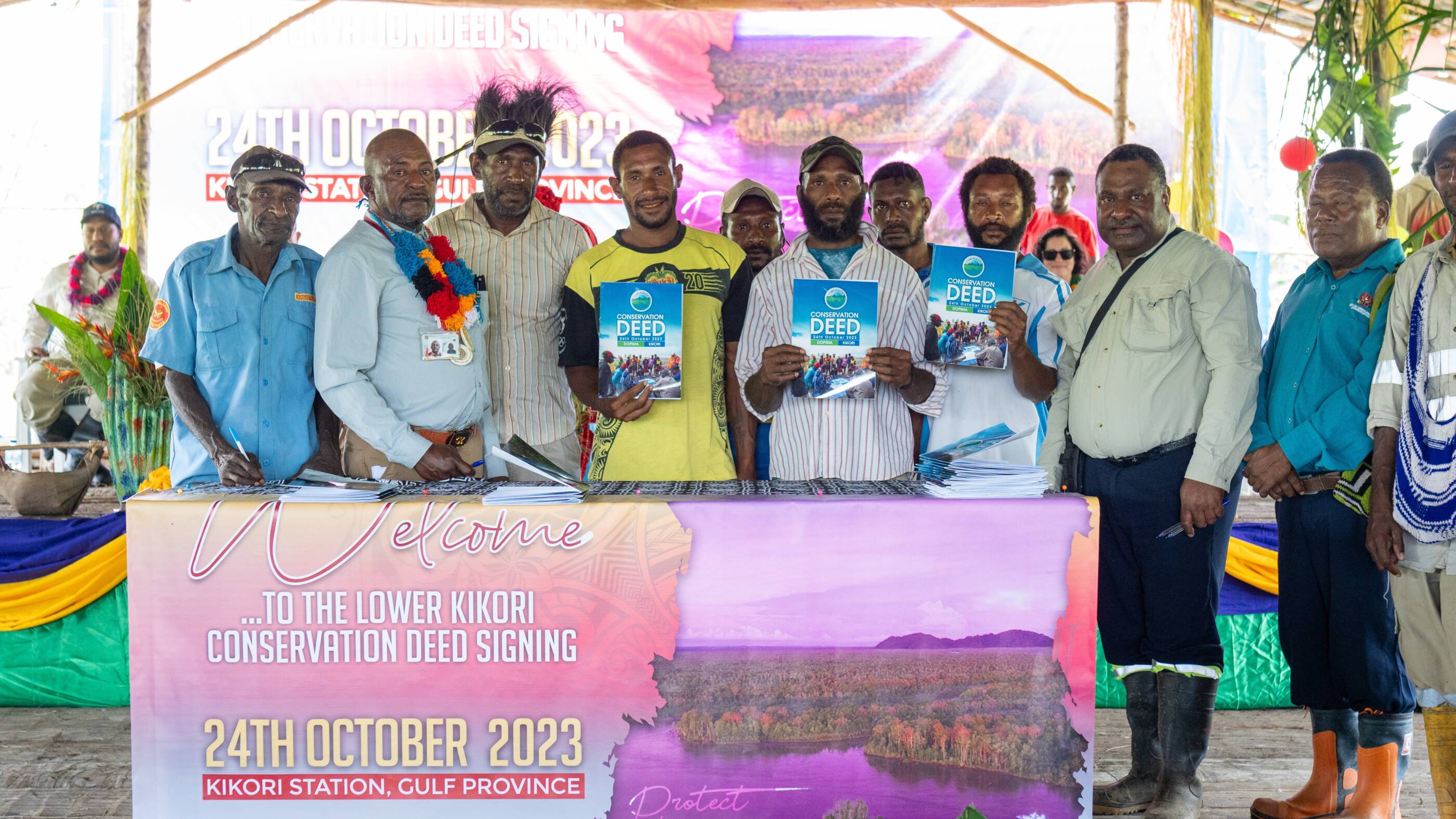

Papua New Guinea clans unite to conserve 20,000 hectares

2 min read

•