selected item

For Dhaval Bhandari, when innovation flows, the world grows

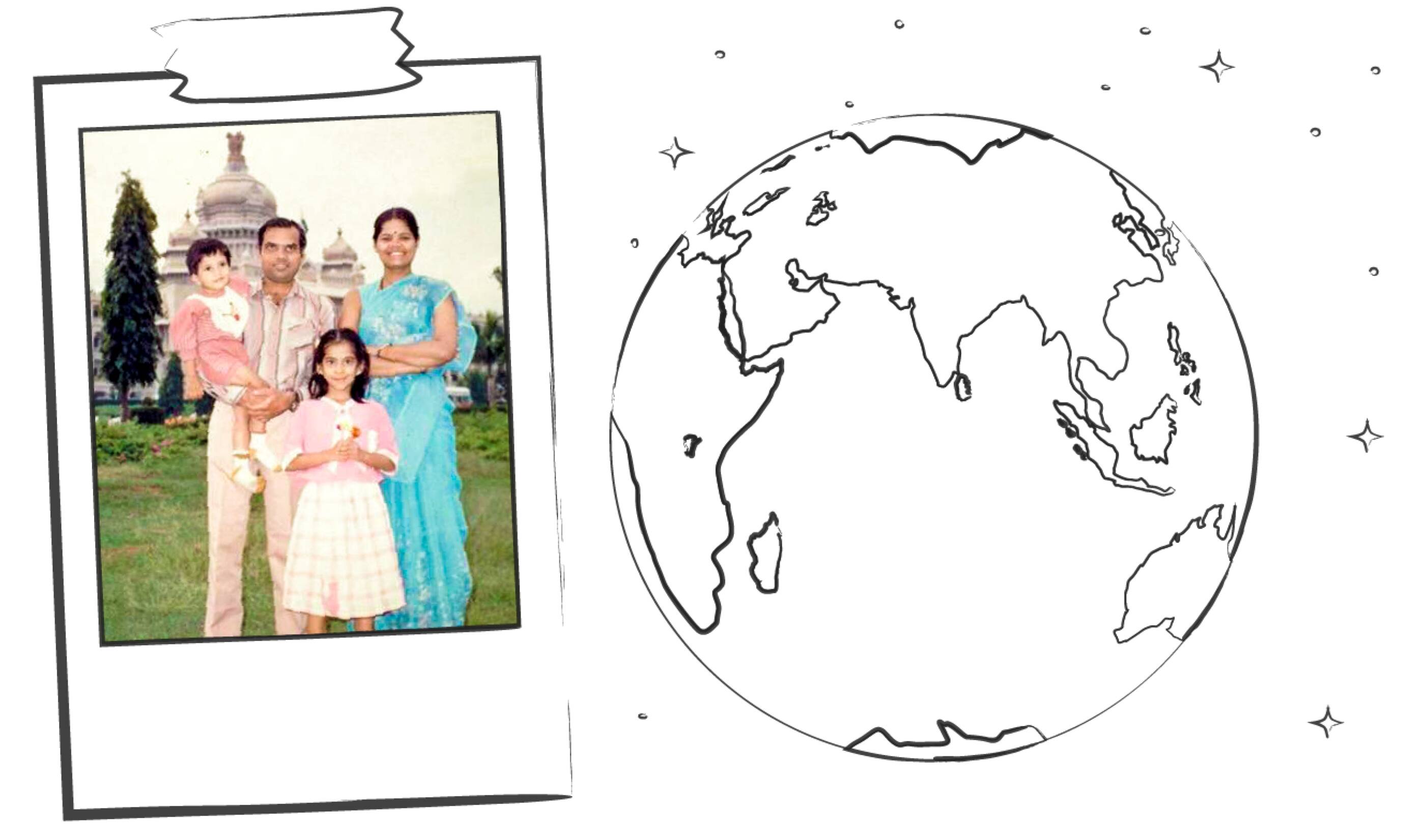

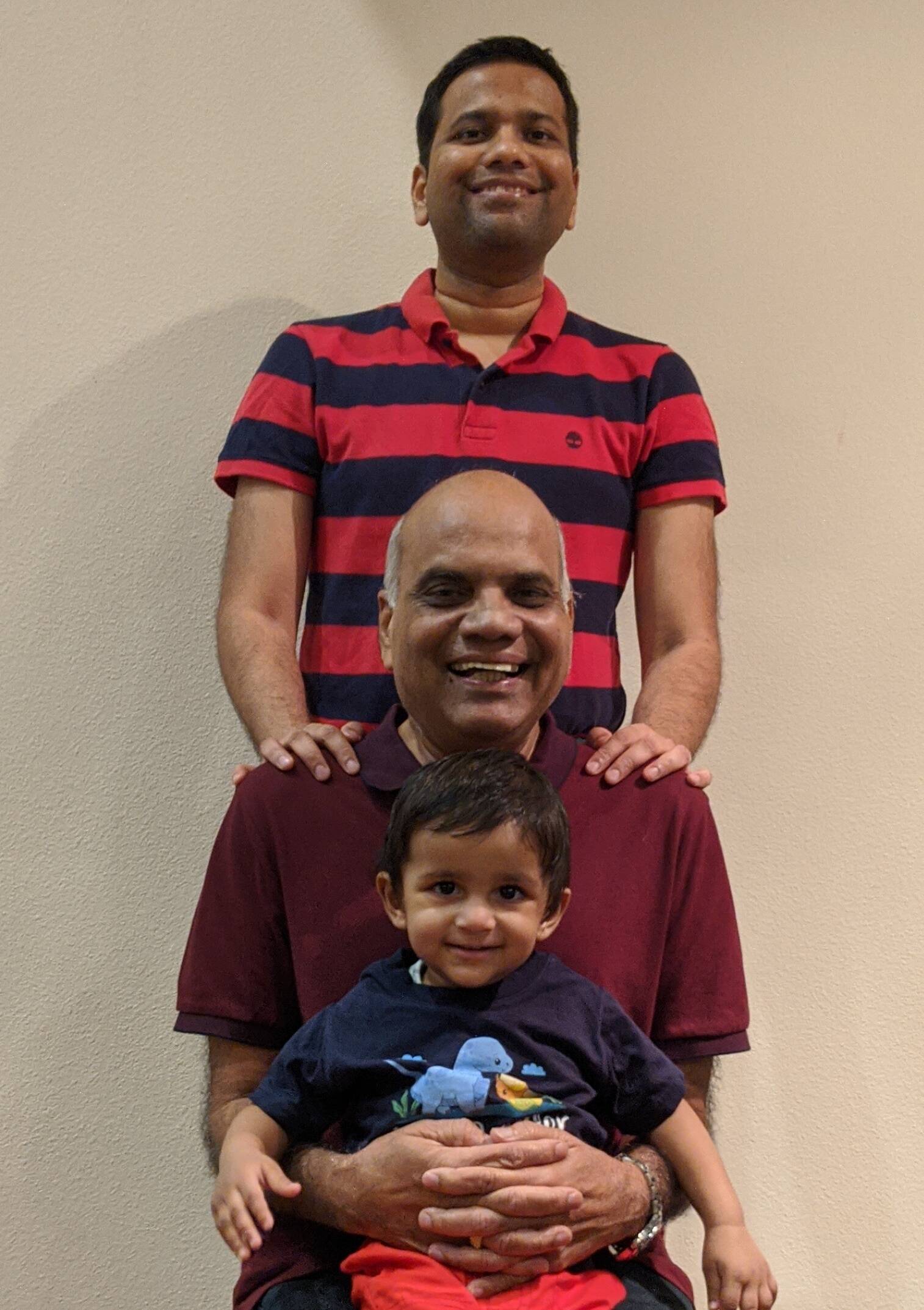

My father worked for India’s national oil company, which means I’ve spent a lifetime immersed in the oil and gas sector. At teatime, in addition to talking about school, our family also discussed how geopolitical forces affect global oil markets. Our neighbors were our father’s coworkers. And our refrigerator boasted the company logo: “Oil flows, nation grows.”

To me, energy was everything … and it still is.

Following in my father’s footsteps led me to becoming a chemical engineer and, eventually, securing a spot with ExxonMobil, where I have a role in helping shape the energy landscape for generations to come.

But before all that, I spent my childhood in India’s most populous cities, including Chennai, Delhi and Mumbai, where, despite the cosmopolitan setting, the threat of an energy shortage loomed often. At the time, power shortages were frequent, teaching us not to take for granted that the air-conditioning would turn on or the refrigerator would stay cold. My experiences crystalized the importance of energy security.

Access to safe, reliable energy is critical to societal and economic development. That was something my father understood, and a lesson he passed on to me. As a 35-year-old researcher at ExxonMobil, I’m working on projects that couldn’t have existed during his career, but I still prioritize that same goal of improving energy security.

A future in transition

Of course, today’s energy challenges are far from what my father could have imagined. We are in the midst of a major transition, exchanging carbon-intensive fuels like coal for a lower-carbon mix of renewables and natural gas. As a young scientist, I take this transition very seriously. It’s why I got my PhD in chemical engineering from Georgia Tech.

Here’s what we face.

Billions of consumers are joining the global middle class. I often hear from family back home in India celebrating the purchase of a new car or a bigger home. Of course, to fuel their cars, power their homes and jump-start economic enterprise, they will need energy. There is an urgency to global energy demand, and it’s our job to meet it.

However, as I envision the energy future, I also see an opportunity to satisfy those needs with lower-carbon energy. For comparison, I look to cell phones as a source of inspiration. Most cell phone owners in India and many other countries never owned a landline; they jumped right into mobile use. I’m hopeful the same thing could happen for developing nations that are building new energy infrastructures, prioritizing the use of lower-emission energy sources like natural gas and renewables. With these advancements in lower-carbon supplies, we can meet the dual challenge of providing people around the world with reliable energy and fewer emissions.

All it takes is scientific ingenuity and a lot of research.

Doing more with less

That’s where I come in. My role in ExxonMobil Research and Engineering (EMRE) is to help progress groundbreaking technologies and initiatives aimed at meeting that dual challenge.

One particularly important piece of the puzzle, my area of expertise, is advanced separation. Right now, refineries separate the different components of crude oil, like lubricants and gasoline, through a process called distillation – essentially boiling hydrocarbons. That process involves massive amounts of heat, making it energy intensive.

But what if refineries could separate products without heat?

I worked with a team of experts from ExxonMobil, my alma mater Georgia Tech and the Imperial College London to answer that question. Our team developed a new non-phase change approach using filtration. Specifically, we developed membranes that, under the right amount of pressure, could filter at the molecular level at room temperature. When scaled to industrial levels, the technology could significantly reduce ExxonMobil’s energy consumption and emissions – and, in the process, shrink the carbon footprint of everyday products like gasoline and components used to make plastics.

And that’s just the start.

Introducing energy 2.0

Looking ahead 20 years, I truly believe the membrane technology we’re using today to process oil and gas could also be a key enabler to carbon capture and storage, a process called CCS. I became passionate about this research topic early in my career, even before coming to ExxonMobil. At age 26, I worked at General Electric Global Research and became one of the youngest principal investigators for a team of researchers for a U.S. Department of Energy (DOE) grant. My work explored the use of ultra-thin filters to significantly reduce CO2 emissions from coal-fired power plants and yielded promising results in the lab that inspire my thinking today.

The challenge is that, to really make an impact, these technologies need to scale up to real-world use. Refineries won’t accept a technology just because it’s new and sophisticated; it needs to be safe, reliable and thoroughly tested. For scientists, this is when the fun begins. But this is a decade-long process of scaling from a concept in a lab to a robust commercial tool.

For most people my age, it’s tough to think in multiple years, rather than weeks or months. But I often look back just a generation ago to the late 1970s, when scientists began scaling up a new, ambitious method of desalination. Rather than boil sea water to rid it of salt, they created a cutting-edge membrane filter. Many critics derided the new technology, saying it would never work. And yet today, companies are building energy-efficient desalination plants able to filter a record 900,000 cubic meters of water (that’s 240 million gallons) daily using the reverse osmosis membrane technology. Though it took time to scale the idea, we’re seeing an impact that was once unimaginable.

Scientists across the energy sector are hard at work on new ideas just like that one – ideas that could change the world. Now, it’s my turn to progress the scientific breakthroughs that came before me and run with them, expanding their revolutionary ideas into global realities.

After all, a lot can happen in a generation. I should know.

Explore more

Expanding our CCS operations in Louisiana with another project startup

- We are now transporting and storing captured CO2 from the New Generation Gas Gathering (NG3) project in Gillis, Louisiana.

- NG3 is our second active commercial carbon capture and storage (CCS) operation in Louisiana.

- CCS application differentiates Louisiana’s core industries, including LNG, and provides a low-carbon energy solution for data centers and more.

2 min read

•

2025: Taking carbon capture and storage from momentum to impact

- We started up our first commercial CCS operation in 2025 with CF Industries in Louisiana.

- Our CCS portfolio spans multiple industries, with three projects expected to come online in 2026.

- We are targeting a final investment decision on our first Low Carbon Data Center by late this year.

2 min read

•

Capture it. Move it. Store it: Three steps for reducing CO2 emissions

- Want to learn more about carbon capture and storage (CCS)?

- Clay, Mark and Elizabeth are here to help in a video series.

- They explain how CCS works, why it matters and what makes it safe.

2 min read

•

How we’re capturing carbon and storing it safely

- In a new video, our Kathleen Ash explains how we’re keeping carbon capture and storage (CCS) safe.

- We have robust systems to safely transport and store captured CO2 emissions.

- We’re committed to protecting the safety of communities in which we operate.

2 min read

•

Calpine, ExxonMobil sign CO2 transportation and storage agreement for power generation project

- ExxonMobil to transport and store up to 2 million metric tons per year of CO2 from Calpine’s natural gas power generation facility.

- Calpine plans to produce ~500 megawatts of reliable low-carbon electricity, enough to power more than 500,000 homes.

- Project expected to bolster U.S. energy, strengthen industry competitiveness, and create jobs.

2 min read

•

2024: A breakout year for our carbon capture and storage business

- We’re leading the creation of a new industry.

- 2024 was a big year for our CCS business.

- More milestones are ahead in 2025.

3 min read

•